India, a nation with the third-largest air travel market with over 327 million air travellers in the year 2023 , remains curiously absent from the global stage of aircraft manufacturing. While giants like Airbus and Boeing reign supreme, churning out marvels of engineering that grace our skies, the Indian aviation narrative is largely one of assembly lines and import dependency. This begs the question: why the disconnect?

Tech Trailblazers

The Boeing-Airbus Duopoly: Walls Too High to Climb?

The dominance of Airbus and Boeing stems from a potent cocktail of factors. Decades of head start in research and development, colossal investments in cutting-edge technology, and a sprawling global supply chain make them formidable gatekeepers. The complexity and high capital intensity of aircraft manufacturing further act as entry barriers, deterring potential competitors.

India, while making strides in aerospace, lacks the ecosystem for full-fledged aircraft production. We have pockets of expertise in light aircraft and sub-components, but a complete aircraft demands seamless integration of diverse technologies – aerodynamics, materials science, propulsion systems, complex electronics – often beyond our current capabilities. Additionally, the fragmented nature of our aerospace industry hampers collaboration and resource pooling, further stunting growth.

India’s Challenges:Aeronautical Dreams, IT Realities

India, despite its potential, faces several hurdles on its path to becoming an aviation powerhouse.

- Fragmented Ecosystem: The Indian aerospace industry lacks the interconnectedness of established players like Europe and the US. With a plethora of small-scale suppliers and limited collaboration between private and public players, achieving the critical mass needed for large-scale aircraft production remains elusive.

- Talent Drain: While India boasts a sizeable pool of aeronautical engineers, many migrate to IT or other sectors due to the limited opportunities and relatively lower salaries in the domestic aerospace industry. This talent drain further hinders the development of a critical mass of skilled personnel.

- Financial Roadblocks: Aircraft manufacturing is a capital-intensive endeavor. Attracting substantial private and public investments into research, development, and infrastructure remains a challenge for India. The high risk associated with such ventures further discourages potential investors.

- Technological Lag: Bridging the technological gap with established players is a persistent obstacle. Access to cutting-edge materials, advanced manufacturing techniques, and proprietary software poses significant challenges for Indian companies.

The IT Mirage:

In recent years, the allure of the booming IT sector has further eroded the appeal of aeronautical engineering. High salaries, quicker career progression, and a perceived “ease of entry” have led many aspiring aeronautical engineers to abandon their dreams of soaring through the skies for the comfort of cubicles. This shift in career preferences exacerbates the talent drain in the aerospace industry, creating a vicious cycle that hinders India’s progress.

Breaking the Ceiling:

Despite these challenges, a glimmer of hope persists. The Indian government’s ambitious initiatives, such as the “Make in India” program and the establishment of special economic zones for aerospace, aim to create a conducive ecosystem for domestic aircraft manufacturing. Additionally, private players like Tata Advanced Systems and Mahindra Aerospace are making significant strides in developing indigenous aircraft components and sub-systems.

Furthermore, the rise of electric and hybrid aircraft technologies could offer India a potential entry point. These new technologies require different skillsets and manufacturing processes, potentially leveling the playing field for smaller players. By focusing on niche segments and fostering innovation in these emerging areas, India could carve its own space in the global aerospace market.

The Role of Technology:

Technology, often seen as a double-edged sword, holds both challenges and opportunities for India. While advanced manufacturing techniques and automation may reduce entry-level jobs in traditional manufacturing, they also open doors for new skillsets in areas like robotics, data analytics, and cyber-physical systems. Embracing these technological advancements and developing a workforce equipped with these skills will be crucial for India to compete in the future of aircraft manufacturing.

Taking Flight: Initiatives to Propel India into Aircraft Manufacturing

To soar in the elite company of Airbus and Boeing, India needs a multi-pronged approach that fosters innovation, collaboration, and talent retention. Here are some initiatives the Indian government and industrial tycoons can implement to make this dream a reality:

Government Thrust:

- Public-Private Partnerships (PPPs): Create PPPs to establish world-class research and development (R&D) centers focused on indigenous aircraft design and technology. These centers can attract global talent and generate valuable intellectual property.

- Financial Incentives: Offer tax breaks, subsidies, and low-interest loans to both private and public aerospace companies. This will reduce the financial burden and encourage larger investments in the sector.

- Streamlined Regulations: Simplify and expedite licensing processes for aerospace businesses to attract foreign investment and expedite project approvals.

- Skilled Workforce Development: Allocate funding for specialized training programs in cutting-edge technologies like composite materials, robotics, and advanced manufacturing techniques. Partner with leading universities and international institutions to create world-class aerospace education programs.

- Focus on Niche Markets: Prioritize research and development on regional aircraft, drones, and electric-hybrid planes where India can leverage its technological skills and address growing market needs.

Industrial Tycoons’ Role:

- Collaboration and Consolidation: Encourage consolidation within the Indian aerospace industry to create larger, more competitive entities with the resources and expertise to compete globally. Foster collaboration between private players and public sector undertakings (PSUs) to share knowledge and resources.

- Technology Acquisition and Transfer: Partner with established aircraft manufacturers for technology transfer agreements and joint ventures. This will provide critical access to knowledge, tools, and best practices.

- Invest in Innovation: Set up in-house R&D facilities and invest in cutting-edge technologies like artificial intelligence, additive manufacturing, and advanced materials. This will ensure India is at the forefront of future advancements in the industry.

- Mentorship and Talent Cultivation: Create mentorship programs where experienced industry professionals guide young engineers and entrepreneurs. Establish internship opportunities within aircraft manufacturing companies to expose students to real-world challenges and inspire them to pursue their dreams.

Rekindling the Dream:

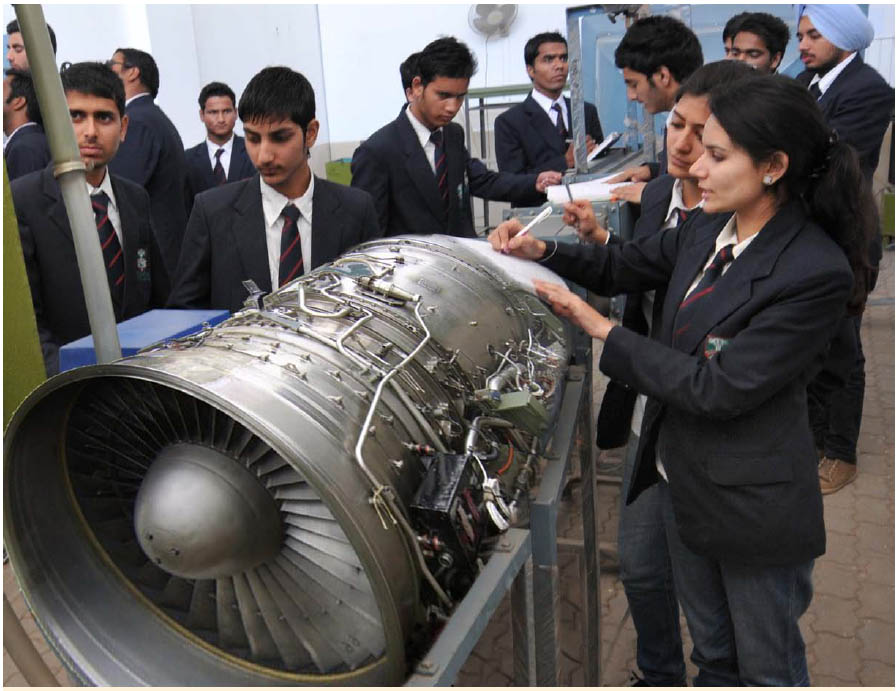

- Image Improvement: Promote the allure of a career in aerospace through media campaigns, industry visits, and workshops. Showcase the exciting advancements and potential of the sector to attract young minds.

- Competitive Compensation: Offer salaries and benefits comparable to other high-demand sectors like IT to retain skilled engineers within the aerospace industry.

- Entrepreneurial Ecosystem: Foster an ecosystem that encourages and supports startups in the aerospace sector. Provide incubation spaces, access to investors, and mentorship programs to nurture the next generation of Indian aircraft pioneers.

By taking these initiatives, India can create a fertile ground for its aerospace industry to blossom. These collaborative efforts will not only propel India toward membership in the elite aircraft manufacturing club but also inspire the next generation of engineers to embrace their sky machine dreams and turn them into reality.

Remember, the journey won’t be easy. It will require a sustained commitment from all stakeholders, overcoming bureaucratic hurdles, navigating complex supply chains, and weathering fluctuations in market demand. But the rewards – a self-reliant aerospace industry, high-skilled jobs, and the pride of taking to the skies on Indian-made wings – are well worth the pursuit.

This is just a starting point, and further research and exploration can deepen the discussion and add even more actionable steps to this plan. Let’s keep the conversation going and work together to make India’s aerospace dream a soaring success!

Conclusion:

In conclusion, the dream of an India at the forefront of aircraft manufacturing remains alive, flickering beneath the wings of ambition and opportunity. It’s a journey demanding collaboration, investment, and a relentless pursuit of technological advancement. For the young generation of aeronautical engineers, this quest promises not just a premium career path, but a chance to etch their names onto the fuselage of history.

And the future of air travel itself is about to undergo a monumental transformation. Drones, once relegated to military missions and hobbyist enthusiasts, are poised to take center stage. From revolutionizing logistics and delivery to reshaping agriculture and disaster response, these unmanned aerial vehicles hold the potential to redefine the very way we navigate our skies.

But are we prepared for this drone revolution? What ethical dilemmas does it pose? How will it impact existing industries and reshape our cities? These are questions that demand our immediate attention, and we invite you to join us as we delve deeper into this fascinating world in our next article, where we’ll explore the trending drone technology and navigate the complex perceptions surrounding it. Buckle up, dear reader, for the skies are about to get a whole lot busier and the future, much more fascinating.

Let the journey continue!

Read more: Titanic Tech Fails: Can India Learn from Disaster and Lead the Next Underwater Era?